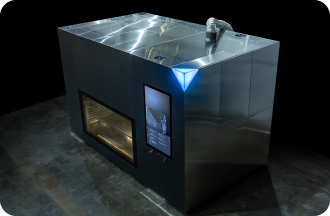

AnyForm Factory™ additive manufacturing system

The AnyForm Factory AM system is an advanced, large build volume, granular-based 3D printing system. It is the only additive manufacturing system that is fully compliant with the requirements of AnyForm 3Dware – Versatile Thermoplastics Particle Manufacturing (VTPM), proprietary breakthrough technology for additive manufacturing.

The AnyForm Factory can print from the widest range of standard polymers and high-temperature engineering plastics. Dual extruders and wide operating temperature range make it very versatile.

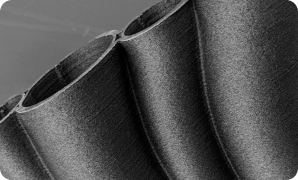

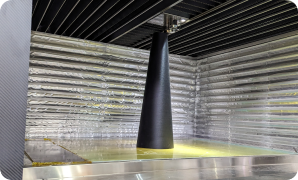

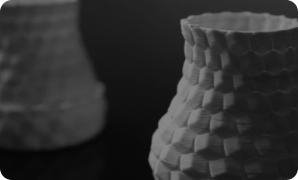

The system is capable of rapidly producing objects of complex geometry and high quality.

AnyForm Factory rapidly builds large, strong, complex, light objects, either one-off or multiples, that traditional manufacturing equipment cannot make, reducing waste and costs.

Ideal for any size prototypes, short-run production, on-demand manufacture, and research of new materials and properties.

Some of the individual features of the AnyForm Factory system can be found in other 3D printing systems. But it is the combination of all these capabilities that sets the AnyForm Factory AM system apart as the most versatile industrial 3D printer on the market. The narrow range of materials that most 3D printers work with often makes it necessary to change printers for different jobs. In the CoE this would mean having several (expensive) machines for research and production. AnyForm 3Dware's motto is "Change the settings, not the printer." A single AnyForm Factory AM system can do the jobs of several different printers with other systems.

The AnyForm Factory was designed to meet the specific needs of today’s manufacturers, as well as those of R&D centers. Full information on the AnyForm Factory additive manufacturing system can be found on the AnyForm Factory website.